Market place: beverage manufacturer

Industry: F&B

Scale: 1000 +

Goal: Improving the quality of product presentation in retail chains, automation of reporting.

Task: In order to control the placement in the retail stores, it is extremely important to promptly receive accurate information about the technical condition of refrigerators, quality of facing and completeness of the product presentation. Manufacturers solve these challenges by manually gathering (photographing refrigerators) by trading store staff and/or sales representatives, and semi-automatic processing that entails the following issues:

- Large time delays.

- The low level of veracity.

- Incomplete information.

- Prolonged reaction time.

- Poor decision making.

Current quality of product presentation in retail networks: from low to medium.

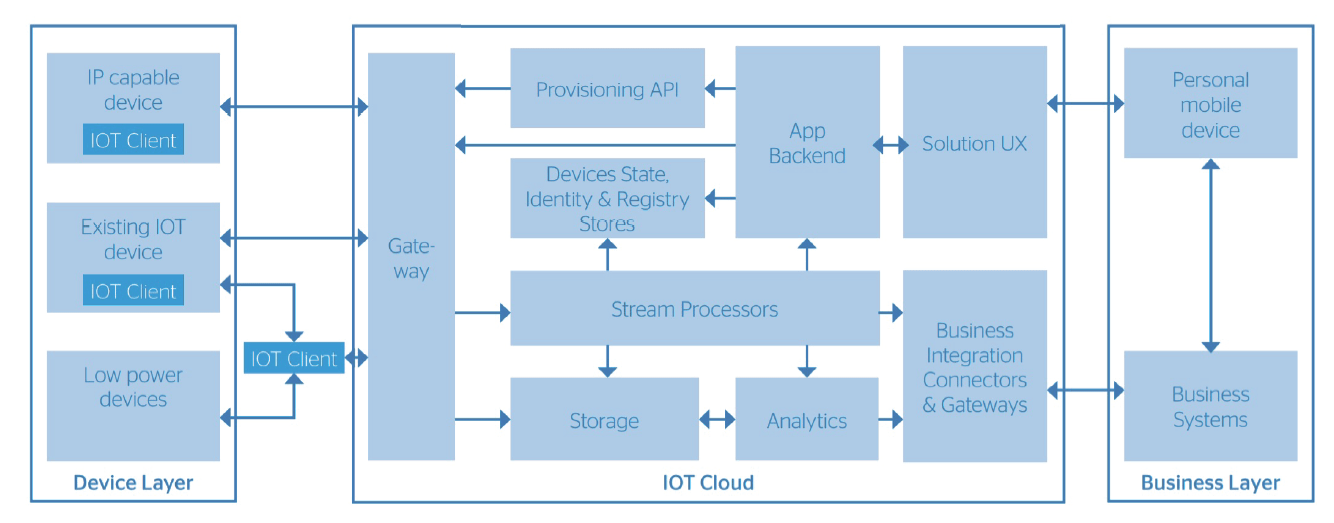

Technology: We have proposed a comprehensive solution that allows monitoring of facing and completeness of the assortment as well as the technical condition of equipment in online mode. It also automatically sends notifications to the service department in case of the inconsistency of the goods presentation and/or the location of the refrigerator.

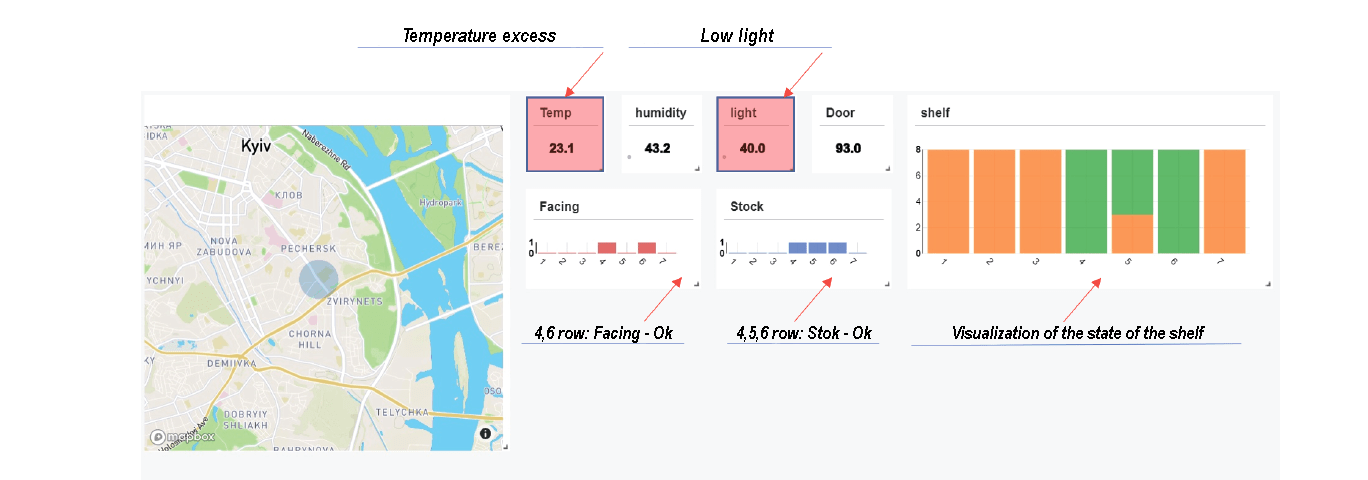

For data processing and visualization we have offered а cloud solution, for tracking of key parameters we have developed a software and hardware complex with a set of sensors, placed directly in refrigerators, allowing continuous monitoring of critical parameters such as:

- Power supply.

- Temperature and humidity.

- Lighting of the showcase.

- Opening doors.

- А-GPS coordinates.

- Facing.

- Product availability.

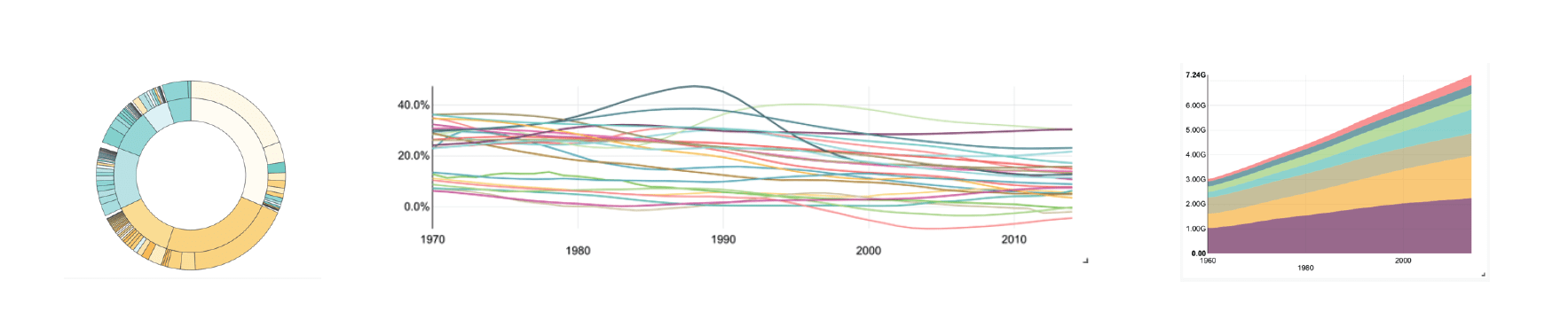

The collection, accumulation, and processing of data regarding the quality of facing, sales dynamics, technical condition of equipment, etc., allows to identify correlations and use the data for business intelligence and further effective decision making.

Solution advantages:

- on-line data acquisition;

- high veracity of data;

- notification with zero time delays;

- high-quality decision making based on high-precision analytics;

- extended analytics to evaluate existing marketing activities and plan new ones.

Proactive approach: an automated data collection from the sensors, which are placed directly in refrigerators, automated notifications and advanced high-precision analytics:

- Advanced analytics using machine learning methods will provide interpretation and understanding of data for decision making.

- Automated notification based on composite scenarios with elements of proactivity, ensures prompt elimination breakdowns and prevention of downtime.

- The solution architecture provides a platform for integrated data analysis of refrigerators together with data from other sources for effective data-based decision making.

- IoT for Coolers services can supply data for other systems, for example, for user applications with information about the location of the nearest store with cold drinks.